Ruggedized electronics are found worldwide in many markets today: military, industrial, marine, mining and others. While they are all seeking the benefits of longevity and durability, each application tends to have its own set of requirements. Sometimes these specifications come with a higher price tag when compared to off the shelf solutions that appear to fit the need. The temptation is to save money in the short term, hoping that the alternative from a lesser known supplier will perform as needed. But sacrificing either quality or requirements is a risky proposition.

Risky Business

Often, the risk isn’t immediately obvious. Competing options appear to meet the specifications. In other cases, buyers will knowingly take a chance, thinking that under-specking a piece of equipment won’t really matter. “Close enough!” they tell themselves. When are the consequences discovered? In the field – wherever the equipment is ultimately being used. Equipment that is meant to last fails on day one. The situation spirals quickly. Labor cost is wasted, downtime ensues, time is lost. People’s safety could be at risk.

Not to be all gloom and doom, but it usually gets worse. Often, the next course of action is to try and fix the mistake. The hope is by modifying the failed component, it could be brought up to the initial requirements. But this rarely works out. Eventually, it fails again. The cycle may be repeated until the buyer finally acknowledges that they’ve been defeated. It’s an unfortunate situation: an initial good faith attempt to sharpen the pencil results in good money going after bad. And still no viable solution.

The High Cost of Low Prices

For example, in airborne military applications, altitude is of critical concern. A while back, we had an overseas customer come to us with an issue. They quickly learned that off-the-shelf commercial displays from a different supplier weren’t designed to hold up well above 10,000 feet. The screens started falling apart above 10,000 feet. Why? They were not designed using an optical bonding process, which was specifically designed to keep screens operating in extreme environments. This process helps the display withstand shock, vibration and promotes excellent readability, even under intense sunlight. We were happy to welcome them back.

Under-specifying is just one side of this conversation. In other cases, the equipment may meet the stated specifications, but is of inferior quality. For example, the alternative solution may have lower quality cables, connectors or other components. These are just a few of the many places where manufacturers cut corners to earn a sale and beef up bottom lines.

Let’s look at another case. Our GenStar display is the gold standard, used in air traffic control towers around the world. The success of this product has inspired others to come up with a cheaper option. Let’s just say that they aren’t fully compliant, but “compliant enough”. Some buyers gave them a try. However, in safety-critical applications, sometimes commercial-grade just doesn’t cut it. Sunlight readability can be weak. Cables can fail. They can experience video loss. These design failures can possibly lead to catastrophe. Upfront savings, but at what long term cost?

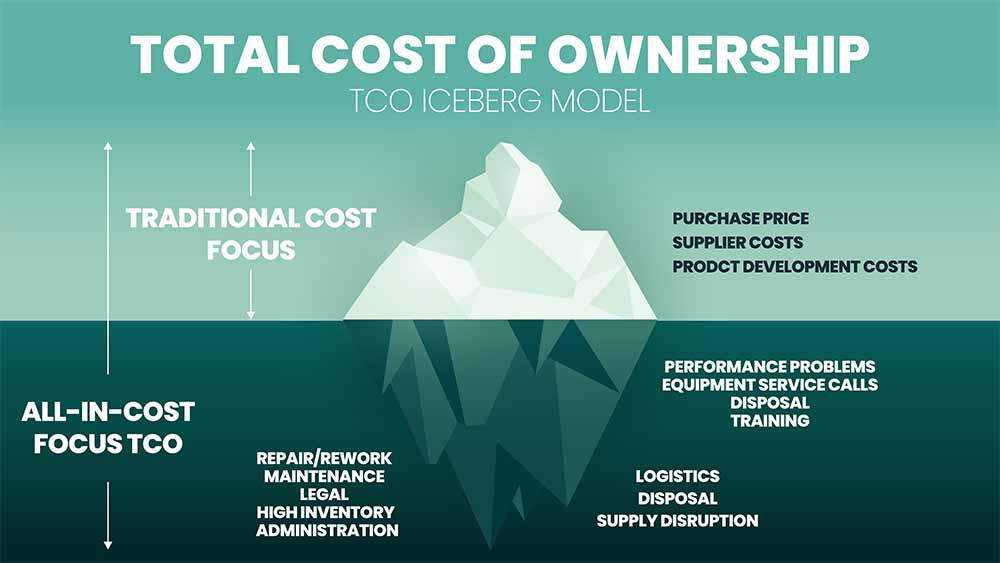

Purchase Price vs. Cost of Ownership

While we appreciate the need to watch the budget, and save where possible, it’s clear that sacrifices should not be made when it comes to safety- and mission-critical applications. Be sure that your purchases meet or exceed required specifications, and that you are sourcing from suppliers known for their quality, and have the certs to back it up. Understand the true long-term costs of your purchasing decisions. Perhaps Ben Franklin said it best, “The bitterness of poor quality remains long after the sweetness of low price is forgotten.”