Enhancements Overview

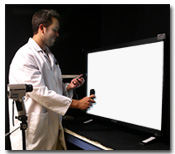

Each display part number, without regard to manufacturer or size, has its own unique “personality” pertaining to optical performance. General Digital Optical Bonding Laboratories understands this challenge and has successfully implemented test and characterization methods. This allows us to better understand the display’s capabilities and potential for improvement. We have on our premises an Optical Characterization Laboratory for obtaining photometrics on any given flat panel display.

Luminance

In our Optical Characterization Laboratory, General Digital Optical Bonding Laboratories obtains brightness metrics of your display under dark room conditions and three different simulated daylight conditions. We then do an evaluation of the OEM films in the display and provide analysis on the best configuration based on your expected operating condition. We perform multiple iterations of backlight film modifications and submit the data to you, along with our analysis of what the metrics indicate.

Contrast

In addition to our luminance measuring, General Digital Optical Bonding Laboratories also provides you with empirical contrast ratios based on the multiple lighting conditions utilized in the luminance measuring process. This assists in the decision process of which configuration will best suit your application.

Benefits

- Increase brightness up to 100% with brightness enhancement films alone

- Improve display contrast and readability

- Improve display clarity and image quality

- Superior uniformity

- Improved operating temperature range and brightness

Options

General Digital Optical Bonding Laboratories offers both passive and active backlight modifications to improve sunlight readability. Our most efficient and cost-effective solution is the GenFlective™ display, a hybrid of transflective and passive enhancements. We also offer a standard transflective display, which incorporates a highly reflective backlight that reflects ambient light back out of the display. Thirdly, we provide the traditional value-add backlight solution, an active enhancement featuring your choice of standard LED or NVIS backlight technology.

Passive Enhancements

- Consider our own GenFlective™ Technology (PDF)

- Requires no more power than OEM panel

- Dissipates no more heat than OEM panel

- Simplifies integration of value-add display

- Easier to address cooling due to low power

- Can often be combined with other passive enhancements (optical bonding) or active enhancements (sunlight/daylight readable backlights/edge lights)

- Typical enhancement of OEM luminance of 20% to 100%

- Contrast enhancement typically measured in orders of magnitude rather than percentages

A GenFlective-enhanced display is one that General Digital Optical Bonding Laboratories has altered, using passive enhancements, to improve the brightness (transmissive and/or reflective) and/or the contrast of the display. Although each display has its own personality, due to differences in design, manufacturing techniques and in the stock film stack, we can typically enhance the performance of an OEM panel utilizing Optical Management Films, Polarizers and Diffusers, and a multitude of films and coatings (Contrast Enhancement, Index Matched, Antireflective, etc.).

A GenFlective-enhanced display is one that General Digital Optical Bonding Laboratories has altered, using passive enhancements, to improve the brightness (transmissive and/or reflective) and/or the contrast of the display. Although each display has its own personality, due to differences in design, manufacturing techniques and in the stock film stack, we can typically enhance the performance of an OEM panel utilizing Optical Management Films, Polarizers and Diffusers, and a multitude of films and coatings (Contrast Enhancement, Index Matched, Antireflective, etc.). General Digital Optical Bonding Laboratories characterizes your display under dark room conditions and three different simulated daylight conditions. We then do an evaluation of the OEM films in the display and modify this configuration as we deem reasonable. We will perform up to four iterations of backlight film modifications and submit the data to you, along with our analysis of what the data tells us.

General Digital Optical Bonding Laboratories characterizes your display under dark room conditions and three different simulated daylight conditions. We then do an evaluation of the OEM films in the display and modify this configuration as we deem reasonable. We will perform up to four iterations of backlight film modifications and submit the data to you, along with our analysis of what the data tells us.

Transflective Panels

- Although they are designed to reflect ambient light back out the display to augment its performance in direct sunlight, transflective panels have insufficient transmissive luminance (typically ~200 nits) to be considered usable in diffuse lighting conditions where direct sunlight is not available (e.g., cloudy or rainy days).

- Additionally, transflective panels are only available in a limited range of display sizes and resolutions.

Active Enhancements

As more of today’s applications require brighter displays, LED backlighting and other technologies have been developed to achieve and maintain the required brightness levels of today’s displays.

- Sunlight readable, standard luminance, NVIS-compatible options available

- High color gamut achievable with high power LEDs

- Lower EMI (Electromagnetic Interference) Emissions

- Lower Power Consumption

- Extended Life Expectancy

- Lower Heat Emissions

- Potentially Lower-Profile-Than-Typical Backlight Replacement Techniques

- GD configurations are designed to meet MIL-DTL-901, MIL-STD-810, MIL-STD-461 and more

- Readily dimmable to very low levels without flicker

- Wide thermal range

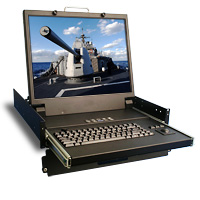

General Digital’s extensive variety of monitor kits and industrial-/military-grade monitors provide our customers with a solution for virtually any type of application or environment.

Customers may request integration of our sunlight readable LCDs into the rugged display product of their choice, as well as NVIS- and NVG-compatible LCDs. The two work well together.

Please feel free to contact a Sales Engineer to discuss your options and configuration requirements.

Sunlight Readable LCD Displays from General Digital

Selecting an LCD monitor for “daylight” jobs isn’t an easy task. But don’t worry–it’s not your fault. On most typical flat screen computer monitors, the LCD panels only produce between 200 and 350 nits of backlighting. For daylight and sunlight readability, this is not enough luminance to create the high contrast necessary to make monitor displays visible against glare.

Daylight Readable and Sunlight Readable LCD technology takes backlighting to the next level. In order to be properly viewable during the day, whether outdoors or indoors in high ambient lighting, General Digital configures its daylight readable flat panel screens to produce at least 343 nits of luminance. To guarantee color visibility in direct sun, our sunlight readable flat panel displays produce at least 686 nits of luminance.

Thanks to extra effort and extensive research into outdoor display visibility, General Digital has created a set of industry-leading high brightness monitors. Most of our display products are engineered to go wherever you need them and work flawlessly for years—decades even.

Within the photometric data, General Digital provides a Weber contrast and class value for each of the display configurations. This information describes the degree of sunlight readability per MIL-STD-3009. The chart provided below summarizes these values. For additional information, read our MIL-STD-3009 Sunlight Measurement Test Setup white paper.

WEBER CONTRAST LOOKUP CHART1

| Contrast Range | Class | Short Description | Ideal Applications |

|---|---|---|---|

| 0 to 1.49 | Not sunlight readable | Not suitable for direct sunlight use | |

| 1.50 to 1.99 | Numeric ONLY | Useful for numerics in direct sunlight | |

| 2.00 to 2.99 | Alphanumeric | Useful for characters and numerical data | |

| 3.00 to 4.659 | Graphic symbols and alphanumerics | Useful for characters, numerical data and static images | |

| 4.66 to 10.29 | Acceptable video performance | Useful for characters, numerical data, static images and low quality video (6 √2 shades of gray counting off as 1) | |

| 10.30 and higher | Best case video performance | Useful for characters, numerical data, static images and high quality video (8 or more √2 shades of gray counting off as 1) | |

| 1 Contrast range and descriptions obtained from page 34 of MIL-L-85762A. | |||

| Read the Weber Contrast Class white paper to learn more about the true measure of sunlight readable displays | |||

Available Sunlight Readable Displays

We have several models that are UL and FCC certified, as well as uphold the standards of military requirements, ensuring that our sunlight and daylight readable options are durable and of the highest quality.

Below is a selection of our product families that can be equipped with high brightness displays for outdoor and high ambient lighting use. Mouse over each product name for a brief description and, if you like, follow the link to the product page for detailed information.

Sunlight Readable and LED Backlights Documentation

All documents will open in a separate browser window.

White Papers

![]() Not All Brightness Is Created Equal – A Discussion of LCD Brightness Values for the Real World

Not All Brightness Is Created Equal – A Discussion of LCD Brightness Values for the Real World

![]() Weber Contrast Class – The True Measure of Sunlight Readable Displays

Weber Contrast Class – The True Measure of Sunlight Readable Displays

![]() MIL-STD-3009 Sunlight Simulation and Measurement Test Setup

MIL-STD-3009 Sunlight Simulation and Measurement Test Setup

Data Sheet

![]() Sunlight Readable/NVIS Dual LED Driver for LCDs Data Sheet 999-0421-406

Sunlight Readable/NVIS Dual LED Driver for LCDs Data Sheet 999-0421-406

Article

![]() Déjà Vue – Finding a Better Path to Specifying an Enhanced LCD to Meet Your RFQ

Déjà Vue – Finding a Better Path to Specifying an Enhanced LCD to Meet Your RFQ