General Digital’s new Dedicated Applications Platform™ (DAP) is a revolutionary firmware platform hosted on a COM Express module that creates a hardware agnostic environment that can evolve alongside your program. The DAP lives in between the application software and the processor, allowing hardware components to be interchanged without the software ever knowing.

This means that those costly redesigns are a thing of the past. The creation of a hardware agnostic interface means that your core application needs to be developed and validated just once, and then ported transparently as the underlying hardware and operating system evolve.

One way to think about this is the way the clutch of a car decouples the engine and gears. Imagine needing to completely reconfigure the engine every time you change gears—the time and expense will add up quite quickly. This is what can happen to embedded software when the processing hardware goes obsolete, a costly and time-consuming process.

With the DAP, now we can maintain the “clutch” and change “gears” (processors) to keep the “engine” (embedded software) running with minimal cost and little to no downtime.

By leveraging our new DAP, we’re able to provide our customers with benefits such as:

- Increased customization of form, fit, and function

- Choice of secondary and tertiary component alternatives to maintain or prolong production life with like or equivalent

- Specify military-grade components (as required)

Developed in support of multiple U.S. military programs, this platform enhances our ability to easily configure products to meet complex requirements. The implementation of our own embedded computer-on-module technology greatly enhances compatibility with other systems, allowing us to provide highly customized solutions for our customers using military-grade components.

The platform works with a variety of operating systems (Linux, Windows, RTOS, and more) and hosts up to 8 USB ports, as well as other commonly used I/Os. Other features supported include:

- Active and passive cooling

- DisplayPort, DVI, LVDS, and Dual DisplayPort outputs

- Multiple gigabit Ethernet ports

- mSATA and SATA for SSD’s or other storage devices

- Keypad control (status LEDs including a breathing LED for sleep mode)

- Coin cell battery for RTC

- Bootloadable functionality available for our Onboard MCU for Field Programmability

- Touch Screen compatibility

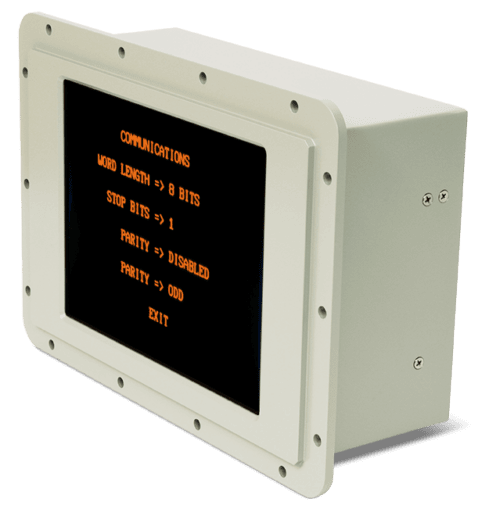

- Serial control

- Analog input/output for features such as temperature sensors, backlight control, or other peripherals

- mPCIe card interface

- Including support for Fiber Network, CANbus, Wi-Fi, Bluetooth, and other high-speed devices)

General Digital’s new Dedicated Applications Platform™ is currently available in our Saber Standalone and other ruggedized workstations, and will be integrated into our upcoming VuePoint IV. This capability further supports our mission to provide the best possible products at the lowest feasible cost to be deployed in the world’s harshest environments for decades to come. It’s one of the many ways that we continue Engineering What’s Next.