By necessity, most equipment used by the armed forces must, at a minimum, be rugged, portable, and lightweight.

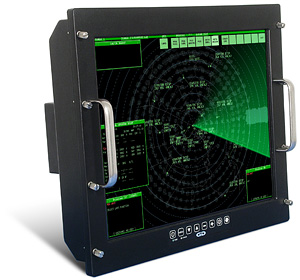

As LCDs (Liquid Crystal Displays) are much smaller, lighter, and more power efficient than CRTs (Cathode Ray Tubes), they are a natural choice for most military applications. In the confines of a naval vessel, armored combat vehicle, or Army transit cases carried out onto the battlefield, LCD monitors can easily display critical information with a smaller footprint.

One useful feature, pioneered by General Digital Corporation, is the flip-up (or flip-down) monitor. Mounted on rails, the LCD lays flat in a rack. When needed, an operator pulls the LCD out and flips it up to view. If desired, the LCD enclosure can be configured with a keyboard and integral pointing device, such as a touch pad or trackball. This maximizes the use of space, which is often in short supply.

Often, the military requires specialized characteristics, such as NVIS (Night Vision Imaging Systems) and NVG (Night Vision Goggles) compatibility, sunlight readability, enclosure ruggedization, or any number of contemporary or legacy video signals.

With regard to NVIS compatibility and sunlight readability in military applications, a monitor must be compliant to MIL-L-3009 (formerly MIL-L-85762A). Considering modern warfare, law enforcement and clandestine operational requirements, which increasingly include intense direct sunlight and/or total darkness, there is an increasing reliance on monitors with NVIS compatibility and sunlight readability.

Another requirement for LCD monitors bound for military use is durability and reliability. No one demands more from their equipment than the military, and consumer-grade displays mounted in flimsy plastic enclosures are simply not up to the task. Rugged metal enclosures, special dampening mounts and sealed keyboards are standard issue. The electronics must continue to work flawlessly regardless of the harsh environment, so quality standards must be stringent. Several military standards address the airborne, ground vehicle, and sea vessel ruggedization requirements. These include, but are not limited to:

- MIL-STD-901D – High Shock (Sea Vessels)

- MIL-STD-167B – Vibration (Sea Vessels)

- MIL-STD-810F – Field Environmental Conditions (Ground Vehicles and Systems)

- MIL-STD-461E/F – EMI/RFI (Electromagnetic Interference/Radio Frequency Interference)

- MIL-STD-740B – Airborne/Structureborne Noise

- TEMPEST – Telecommunications Electronics Material Protected from Emanating Spurious Transmissions

Naturally, the video signals an LCD monitor accepts are critical to military operations. The various signals each have their own connector requirements, timing and electrical specifications; each environment requires the best signal that suits the given task. Below is a list of the most common video signals a military-bound LCD monitor could potentially require; however, this is by no means a comprehensive list.

- Analog Computer Video

- VGA

- SVGA

- ARGB

- RGB

- Separate Sync

- Composite Sync

- Sync-on-Green

- DVI-A

- STANAG 3350 A / B / C

- Digital Computer Video

- DVI-D

- DVI-I

- SD-SDI

- HD-SDI

- Composite (Live) Video

- NTSC

- PAL

- SECAM

- RS-170

- S-Video

- HD Video

- HD-SDI

- HDMI

- Other Video Standards

- CGI

- CCIR

- EGA

- RS-343A

- EIA-343A

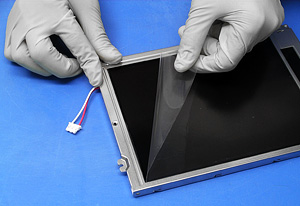

Another important consideration for the armed forces is the integration of display overlays. Shatter-resistant glass is useful in high shock and vibration environments, as well as direct impact conditions. Brightness and contrast enhancing overlays (i.e., coated glass, film, filters) help control reflection and glare anytime the sun is shining on the screen surface. Touch screens improve usability in situations where a keyboard and mouse are not practical to use. Privacy screens keep sensitive information secure. EMI filters shield electromagnetic interference emitted by the monitor and limits the susceptibility of the monitor. Overlays offering any of these capabilities either individually or in combination are commonly required for military applications.

While the LCD monitor industry is comprised of many capable products, in order to provide a military-grade LCD monitor, a manufacturer must couple capability, reliability, and usability in virtually all environments and conditions. An LCD manufacturer needs to intimately familiarize themselves with any special requirements–especially military standards–if they wish to be considered a viable source for any military branch.