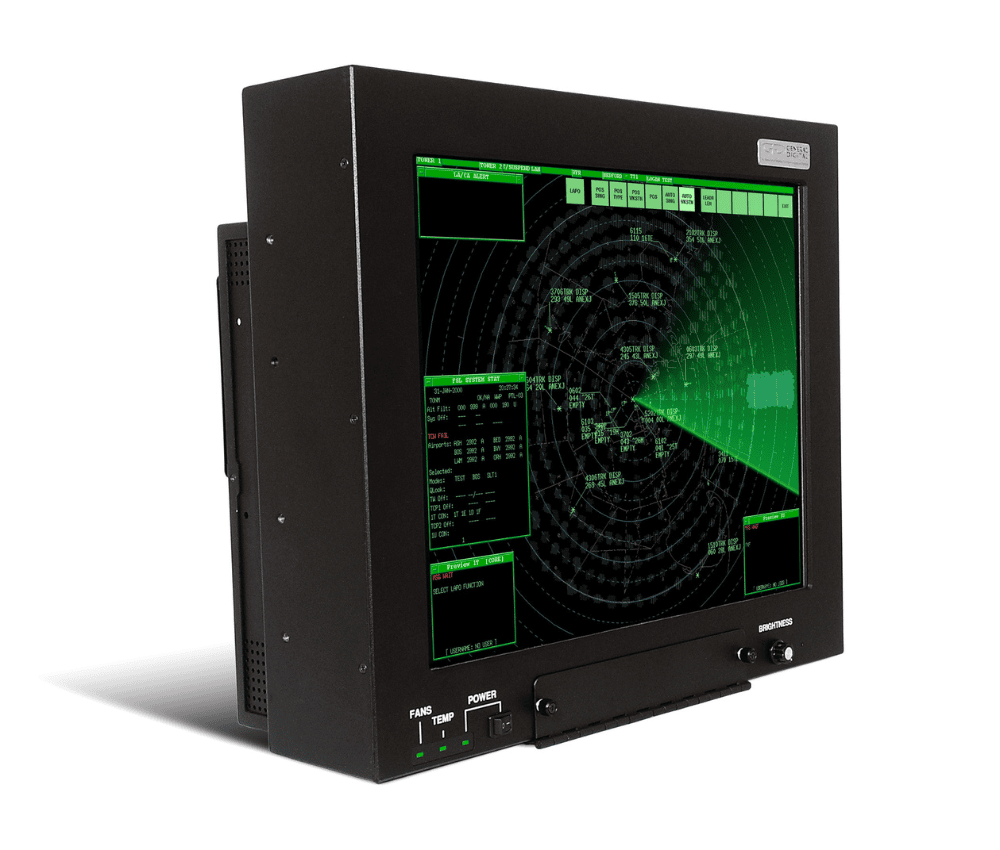

As with previous incarnations, the Genstar IV remains a true drop-in replacement for existing TDM displays.

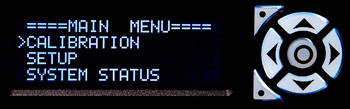

The new User Interface Display (UID) provides users with an intuitive means to configure performance, view status/faults and calibrate/control without having to block flight-critical data on the main display with an On-Screen Display (OSD).

HDMI, DisplayPort and DVI ports have been added in conjunction with the ARGB port to allow additional flexibility in supporting video sources.

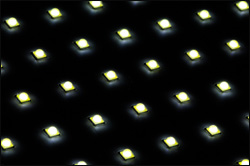

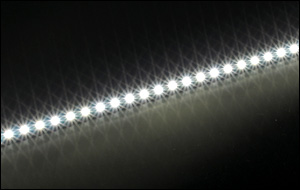

Enhanced Backlight

Depending on the model, the GenStar IV features either an enhanced edge-lit LED backlight or direct-lit LED backlight. The backlights, in conjunction with General Digital’s LED controller, achieve a display brightness from 600 (to comply with STARS Statement of Work) to >1500 nits, with a dimming ratio of >1000:1. The backlights are controlled via PWM, allowing precise and flicker-free brightness control. The MTBF (half brightness life) of the LEDs exceeds 100,000 hours.

User Interface Display (UID)

The Advanced Display Interface System (ADIS) of the GenStar IV takes user control to the next level through the integration of a separate character display to configure performance, monitor health and control the its behavior. The programmable display/keypad eliminates the OSD, keeping the main screen clear for data. It allows the user to access OSD controls, select preferred auto-dimming algorithm and brightness zones, configure alarm reporting, and more. Passcode access limits advanced settings to authorized technicians only.

Adjust system parameters, view system variables, and receive warnings or faults (e.g., LED backlight over temperature, fan failure, and power supply faults).

OSD Functions

Main display On-Screen Display (OSD) menu can be accessed via the character display to avoid blocking mission-critical flight information on the main display.

Backlit Silicone Keypad

Seven white backlit keys: up, down, left, right, center, top programmable and bottom programmable. These keys have 16.7 million color choices and 255 steps of brightness ranging from 0% to 100% brightness, and can be set to automatically dim with main display or dim when inactive.

Status LEDs

Three tri-color (red, green, yellow) status LEDs.

Rotary Encoder Brightness Control

Precisely control the backlight brightness. Adjustable resolution.

Ambient Light Sensor

The GenStar IV boasts dual ambient light sensors to ensure that the display stays at the optimal brightness for the user. The sensors are located on either side of the monitor, ensuring that localized shadows will not impact performance. The ambient light sensor control is firmware-based and can be tailored to meet each specific customer’s needs. Settings can be changed on the fly through the monitor’s UID control panel.

Internal Sensors

Internal sensors are monitored by the control circuitry within the GenStar IV to ensure that the monitor operates within its specifications and prevents critical failures. The controller polls thermal/optical sensors, fan speed, the LED controller, video controller, and power supply for operating status. As needed, the controller can take actions such as increasing fan speed, adjusting brightness or notifying the user of potential issues through the UID.

USB Connectivity

A USB port on the back of the system allows the monitor to be connected to any PC. The connection allows for flash-upgrading of all embedded controller firmware (OSD, Modular Power Supply, Video, LED Backlight, Smart Fan) within the monitor, as well as access to system performance data and user-configurable settings. Monitor performance can be tailored or upgraded in the field without requiring return to the factory.

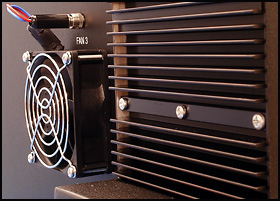

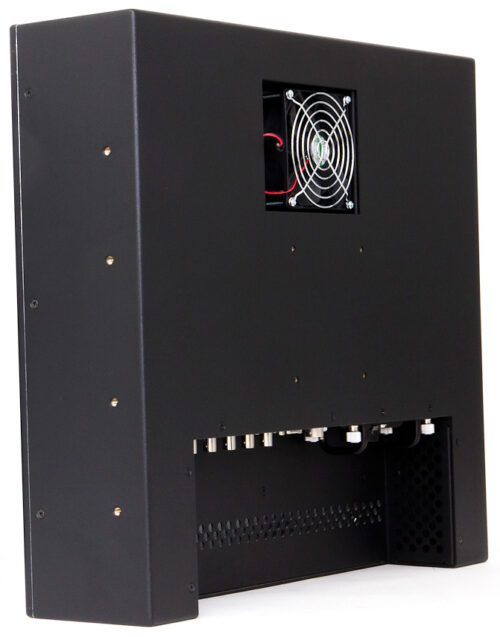

Field-Replaceable Power Supply

The GenStar IV power supply features a modular field-replaceable 100 Watt power supply featuring onboard monitoring of AC/DC power, output current and component temperature. Rear-mounted cooling fans are field accessible for replacement when the user is notified via the UID.

The new power supply features a modular, field-replaceable, power factor-corrected, fully enclosed “brick” that slides in and out of the monitor on alignment rails. When installed, the power supply brick mates with a General Digital-designed circuit board responsible for conditioning, filtering and distributing the power to the other monitor electronic subassemblies. Circuitry on this PCB is responsible for making the power supply meet the inrush and harmonics requirements of FAA-G-2100H and FAA-STD-019E. The brick is mechanically secured in place with captive fasteners located on the power supply’s bezel/mounting bracket.

The supply is capable of running at 50°C without derating. Limits for voltage and current are pre-programmed by General Digital at the factory. In the event that these limits are exceeded, the power supply will automatically disconnect power from the monitor to prevent any critical harm from occurring to the electronics. In addition, a failure signal is sent to the intelligent OSD controller, which triggers a status LED on the front bezel to provide a visual indication of the failure to the user. In addition, the failure is saved in nonvolatile memory. A verbose description of the failure can also be retrieved real time from the Advanced Display Interface System (ADIS).

The supply also monitors other performance; such as the temperature of its critical components, the input and output voltage health, the operating current in use, and the health of the AC and DC power. All of this data is shared with the intelligent OSD controller to be further shared on the ADIS.

- Modular, field-replaceable, fully contained, power supply brick

- Universal input 85–264 Vac single phase 47–63 Hz

- Power factor correction to 95% under full load

- EMI filtered from AC harmonics

- EMI shielded to meet FCC Class A

- Inrush current limited to meet FAA-G-2100H

- Temperature monitoring of critical components

- Output current monitoring

- Power health monitoring for both DC and AC

- Captive thumb screws for ease of service and secure mounting

- AC cable strain relief

- Built-in fuse holder

- Power switch

- Operating temperature range of -40°C to +85°C

- Designed to meet FAA-G-2100H, FAA-STD-019E, UL60950, and FCC class A

Advanced Bootload System

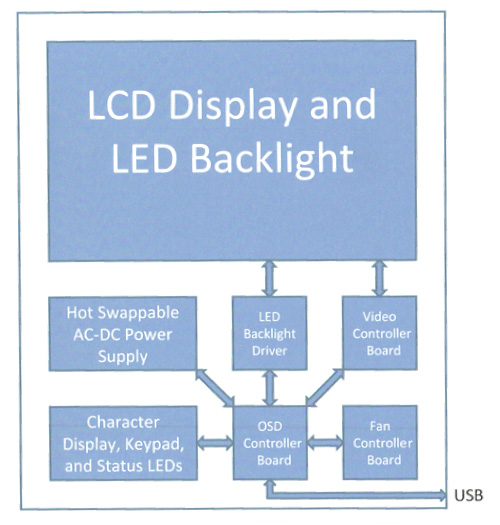

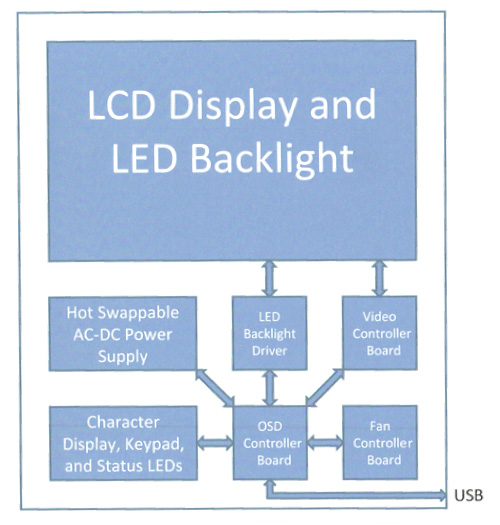

The GenStar IV contains four major controller boards:

- Video Controller

- Smart Fan Controller

- LED Backlight Driver

- OSD Controller

All four of these boards (excludes OEM versions of LED Controller) can be bootloaded via the OSD controller USB (virtual serial port) port. The GenStar IV has been designed to partially run on USB bus power to simplify programming. The following features are available when powered from the USB bus:

- User Interface Display – Fully operational.

- Fan Controller – Bootload firmware, will not power fans.

- LED Backlight Driver – Bootload firmware, will not drive LED backlights.

- OSD Controller – Bootload firmware, fully operational, all I2C devices powered.

All boards are bootloaded using the General Digital Advanced Bootloader Application (ABA). This application simplifies bootloading to a few easy steps within the application. This eliminates any inconvenient procedures, such as power cycling a unit or keying precise button combinations. The union of effective bootloading and versatile hardware allows the user to reconfigure a system’s behavior entirely, without ever leaving the field. The ABA is a .NET utility, which is compatible with Windows® platforms.

Front Enclosure

Dimensions

The GenStar IV enclosure had been intentionally designed to maintain the same height and width dimensions (17.00″ x 19.50″ ) as its predecessors, the GenStar II and GenStar III. The depth has been decreased from 6.5″ to 4.5″. The monitor also includes the same ¼-20 x 0.31″ deep threaded mounting holes, in 4 places on the left and right sides, as the GenStar II and GenStar III, making it backwards compatible with the STARS-approved pedestal mount, ceiling mount and articulating arm. In addition, General Digital’s Panel Mount (Console Mount) Adaptor Bracket (P/N 90-1204-012) is also compatible. Mechanically, the new monitor is a “drop-in” replacement for its predecessors.

Construction

The front bezel is machined from a solid piece of ½” thick 5052-H32 aluminum to provide a stylish and aesthetically pleasing appearance. The corners are rounded to remove any sharp points and to ensure user safety. The corner radii are finished such that they precisely match the radius on the corners of the rear enclosure when the assembly is completed. The bezel is finished with a matte black powder coat finish to minimize reflections.

Display Cutout

The cutout for the LCD is chamfered at 45° to ensure that the panel can be viewed from extreme angles without obstruction.

User Access Panel

A second cutout is provided in the front bezel to provide access to the User Interface Display’s (UID) User Access Panel. The character-based display is covered by a piece of protective glass which can be configured with antiglare (AG) or antireflective (AR) or AR/AG treatments.

Keypad

A 7-button keypad is accessible on the front bezel to navigate the User Access Panel, and can also be programmed to function as “hot keys” to control dedicated functions such as Brightness Up/Down, Contrast Up/Down, or to manually activate/deactivate the UID.

Backlight Brightness Potentiometer

Users can control the brightness of the LED backlight by using the front-accessible potentiometer to control the brightness over a full range from fully off to 100% on. Brightness ranges and limits can be pre-programmed.

Status/Fault LEDs

Cutouts in the front bezel are provided for 3 tri-state LEDs that function as visual status and warning indicators for users. The LEDs are used to report operational status and faults for the power supply (Power Good, Invalid Power, No Power, etc.), video controller (e.g., Standby Mode), internal monitor temperature (Temp. Good, Over Temp., etc.) and fans (Fan Failure). Additional LEDs may be added as an option. The Status LEDs will function in the same manner as the GenStar II.

Ambient Light Sensors

A pair of light sensors are installed in the front bezel facing outward to sense the ambient light conditions. Feedback from these sensors is used by the intelligent OSD board to automatically control the backlight brightness when placed in the Auto mode. Two sensors are provided to minimize the potential of shadows or other obstructions providing false or inaccurate light readings. The ambient light sensors can be disabled so that the backlight brightness can only be controlled manually.

Power Button (Optional)

A DC power switch can be added to the front bezel. This switch will enable/disable DC power to the internal electronics at the power supply. It will not disconnect AC power. When the DC power is OFF, the power supply goes into Sleep mode.

Logo

The customer logo can be silkscreened on the front bezel, provided authorized artwork is supplied to General Digital in advance. This option eliminates the need for the customer to contract and provide General Digital with decals or metal medallions. However, if these methods are still preferred, we can modify the bezel to mill a recess for the logo.

Rear Enclosure

Construction

The rear enclosure is constructed from 0.090″ thick 5052-H32 aluminum. The corners are rounded to remove any sharp points and to ensure user safety. The corner radii are finished such that they precisely match the radius on the corners of the front bezel when the assembly is completed. The enclosure is finished with a matte black powder coat finish to minimize reflections.

Connector Panel

Unlike the prior versions of the GenStar, the GenStar IV has the I/O connector panel installed in a downward facing recess in the rear enclosure. The interface connections for the video I/O, Remote Brightness control, and USB/Maintenance port are distributed on this panel. A summary is provided below.

The modular, field-replaceable, power supply brick, its fuse, and the optional AC Power ON/OFF switch are also located on the connector panel.

Power Supply

A modular, field-replaceable, fully enclosed power supply brick is also accessible from the connector panel. The power supply fuse is accessible from within the CORCOM filter. The power supply is secured within the rear enclosure by external captive hardware mounted to the power supply mounting bracket. A locking restraint for the power cord is also provided to ensure the AC power cord does not become accidentally detached.

On/Off Switch

A rocker switch is provided in the connector panel to activate and terminate the AC power.

Ground Lug

A ¼” ground lug, in accordance with FAA-STD-19E and FAA-G-2100H is located on the connector panel. Optionally, the ground stud can be upgraded to a larger (e.g., 5/16″) lug.

Cooling Fan(s)

A field-replaceable, recessed cooling fan is located on the rear enclosure to exhaust hot air out of the enclosure cavity. Easy to install replacement fan assemblies will be available for purchase from General Digital. Cool air is drawn through the electronics from ventilation holes located in the lower rear section of the enclosure and connector panel area. Users must be careful not to obstruct the ventilation holes.

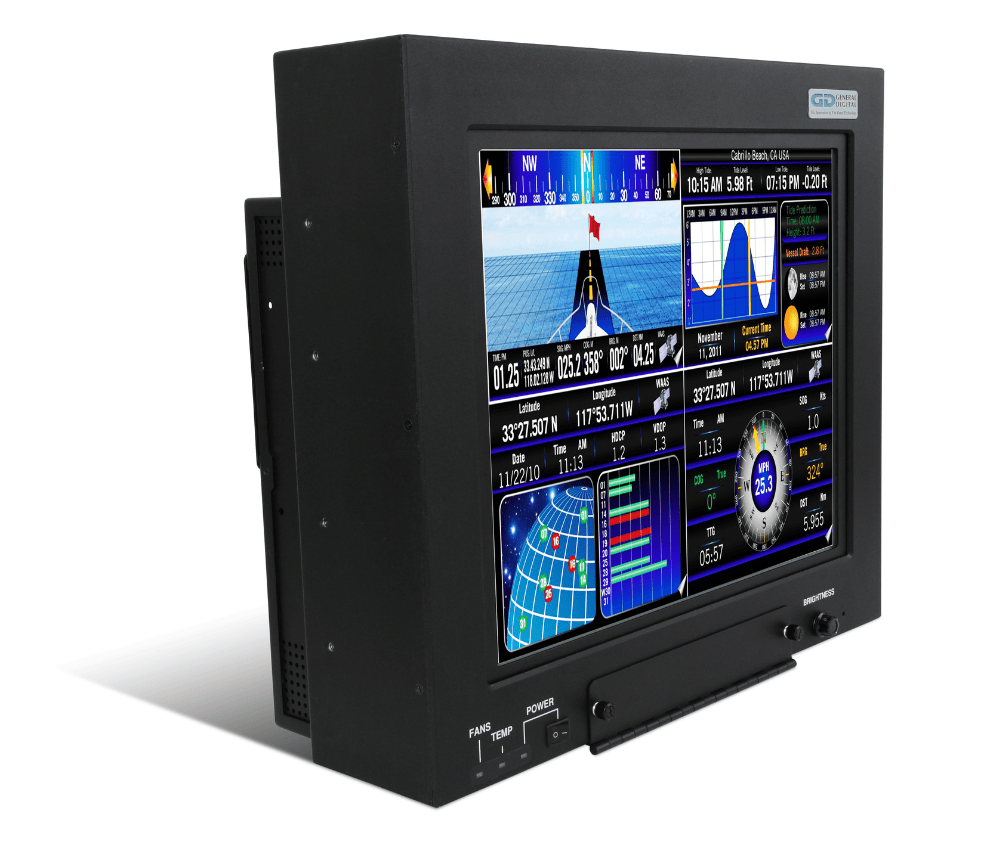

Video Controller

Internal to our LCD monitor is an LCD controller that converts EIA-RS-343 compatible analog RGB color video signals into digital signals required to drive the display. The controller has been customized to support a combination of seven STARS-compliant controllers (TSI 1000, TSI 1100T, TS4000e-LR, RACD, RACD2, RACD3 and RACD4) on two host platforms (SPARC and x86 Processors), while maintaining the ability to switch between any two combinations in less than 650ms.

The controller provides intuitive operation of its controls and calibration through the use of a membrane pad and a series of on-screen menus. All models support the following display image controls: auto and manual setup, brightness, contrast, horizontal position, vertical position, tuning, size, individual RGB adjust, image expansion on/off, system information, run-time counter, and signal level. Advanced features are supported on a selective basis (image rotate and invert, audio controls, advanced scaling).

- Compatible with all STARS-approved video controllers & video modes/timings

- Supports EIA-RS-343, Separate, Composite and Sync-On-Green video

- Custom firmware to support 650 ms switch time between primary and secondary video sources

- Ensures ATC operators can maintain airspace safety even after critical tower computer failure

Mounting Options

Two types of mounting are provided on the rear enclosure assembly.

VESA Mounting

A 100 mm x 100 mm VESA mounting pattern is provided on the rear enclosure to support a variety of industry standard and third-party mounting devices. Optionally, General Digital can add support for a 100 mm x 200 mm mounting pattern; however, this will require a redesign of the power supply enclosure to eliminate conflicts with the mounting studs.

Side Mounting

The monitor also includes the same ¼-20 x 0.31″ deep threaded mounting holes, in 4 places on the left and right sides, as the GenStar II and GenStar III, making it backwards compatible with the STARS-approved pedestal mount, ceiling mount and articulating arm.

Other Mounting Options

Panel Mount Adaptor

The GenStar IV is compatible with the GenStar II/III Panel Mount (Console Mount) Adaptor Bracket (P/N 90-1204-012). The adaptor mounts using the side mounting holes.

Slat Wall Mount Adaptor

General Digital can design a slat wall adaptor bracket to attach to the GenStar IV using either of the two mounting options provided. General Digital would need to know the type of slat wall, the manufacturer and the distance that the monitor would be mounted from the wall. Third-party adaptors may also be available to attach to the VESA mount.

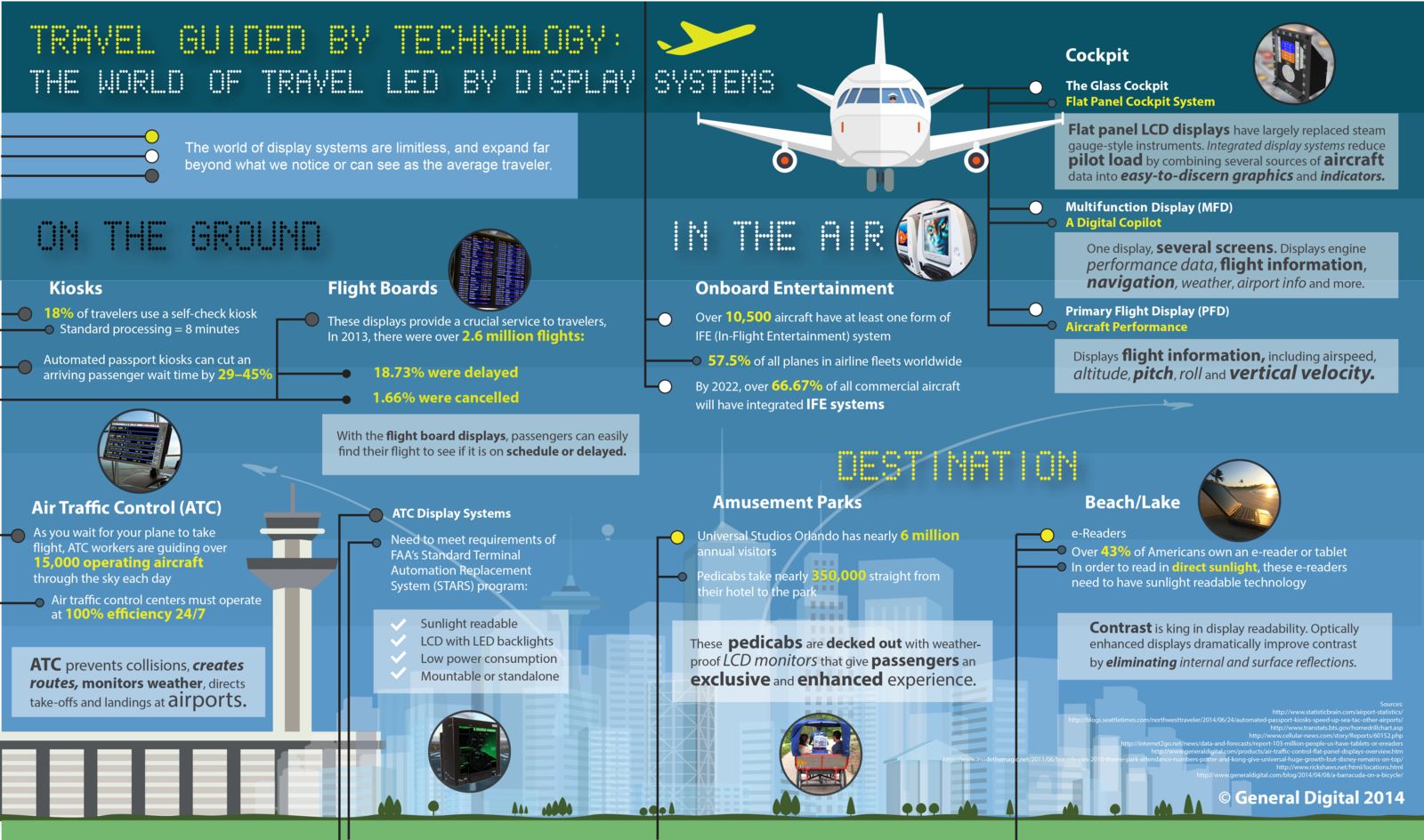

Peak air travel times in the United States see about 50,000 aircraft operating in our skies each day, not counting the tens of thousands of airborne vehicles the world over. It’s no small task for the 15,000 air traffic controllers in airports across the country to prevent these aircraft from colliding into each other.

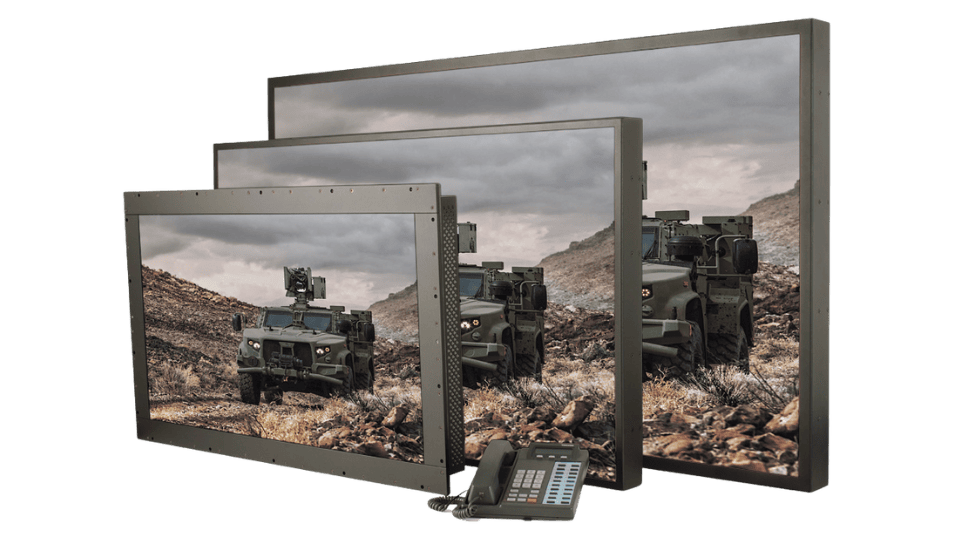

Peak air travel times in the United States see about 50,000 aircraft operating in our skies each day, not counting the tens of thousands of airborne vehicles the world over. It’s no small task for the 15,000 air traffic controllers in airports across the country to prevent these aircraft from colliding into each other. Standard Rugged Displays

Standard Rugged Displays Waterproof/Sealed Displays

Waterproof/Sealed Displays Smart Displays & Computers

Smart Displays & Computers Rack Drawer Flip Display / Keyboard

Rack Drawer Flip Display / Keyboard Rack Drawer Flip Displays

Rack Drawer Flip Displays Large Format Displays

Large Format Displays Open Frame Displays

Open Frame Displays

General Digital is offering the GenStar III and GenStar IV concurrently to accommodate differing air traffic control tower needs and budgets.

General Digital is offering the GenStar III and GenStar IV concurrently to accommodate differing air traffic control tower needs and budgets. Sunlight Readable LED Backlights

Sunlight Readable LED Backlights

We at General Digital are completely responsible for the design and construction of our products, allowing us to maintain nearly total control of their future. To that end, we gladly offer our engineering services to customers who require special customization of our devices to meet their commercial, industrial, marine or military requirements.

We at General Digital are completely responsible for the design and construction of our products, allowing us to maintain nearly total control of their future. To that end, we gladly offer our engineering services to customers who require special customization of our devices to meet their commercial, industrial, marine or military requirements.